|

Carbon & Soils Proximate Fuel Analysis Ultimate Fuel Analysis

|

|||||||||||||||||||||||||||||||||||

Biochar from Biomass Gasification (Pyrolysis) |

|||||||||||||||||||||||||||||||||||

Understanding Biochar

A key in understanding biochar is the dynamic of soil organic matter (SOM) and soil organic carbon (SOC), discussed on our webpage on soils.

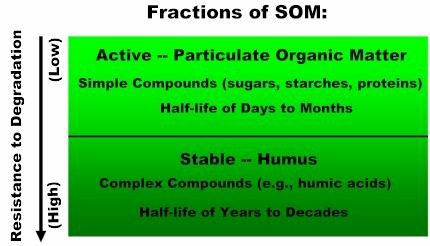

For simplicity, SOM can be divided into two major groups: (1) particulate organic matter (active fraction) and (2) humus (stable fraction) -- which would include biochar. Compared to the short half-life of particulate organic matter, highly stable humus can last in soils for centuries.

The functions of SOM can be broadly classified into the following three groups -- where these groups are not static entities and dynamic interactions occur between these three major components.  Two Aspects of Interests: There are several theories and numerous possible interactions (biological, physical, and chemical) as to why biochar increases soil productivity. Building on our knowledge base of SOM/SOC (including work performed with the U.S. Department of Energy's Oak Ridge National Lab) -- two aspects have especially caught our attention: that produce substances that hold soil particles and nutrients together. plants over time (note the word adsorb, not absorb) -- by increasing the cation exchange capacity (CEC) and also anions of soils. Engineering for Biochar Creation: From an engineering perspective, the most critical aspect in creating biochar is to maximize surface area (pore space) with an objective of trying to create surface areas approaching activated charcoal to maximize the capture/sequester of Greenhouse gases in soils (CO2, methane, nitrous oxide).

In order to achieve high surface areas the key engineering parameter of oxygen starved biomass gasification is temperature formation, where the optimal range is approximately 500 to 700 degrees C (~900 to 1,300 F).

While quite a bit of research is with small scale gasifiers (e.g., laboratory, stove, etc.), our research and demonstration effort is focused on large-scale, commercial up-draft gasifiers where the biochar is a waste product in creating biogas (for end-use applications such as product drying/heating, electricity, steam). In our approach, we extract biochar (just above the incandescent zone) on a semi-continuous basis using nitrogen to “quench and cool” the biochar removed/recovered from the bed cooled to room-temperature for storage and eventual soils application. The recovery of biochar from the gasifier will not significantly impact the gasifier continuous operation of biogas generation for power/heat/steam. It is also important to note that our approach to "quench and cool" in a nitrogen environment is also attempting to address the extremely high carbon/nitrogen ratio of biochar.

| |||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|