|

A Commitment to Renewable Biomass Energy & Global Warming by using Nature's own Power Plants! Through highly innovative agriculture and engineering

research and commercial demonstration partnerships, the Common Purpose Institute is working to grow, harvest, and use fast growing crops (called energy crop or closed loop biomass) and also biomass waste streams (e.g., wood chips from clean yardwaste or forest thinnings, crop residues, etc.) as renewable

energy biofuel feedstocks forPower Generation (electricity, steam, CHP).

Biogas for Manufacturing use (heat for product drying).

Ethanol production (e.g., sweet sorghum, sugarcane).

Biodiesel production (e.g., soybeans).

Oil (Pyrolysis liquids from biogasification waste stream).

Hydrogen production (e.g., transportation fuel sector).

Biorefineries (steam, power, value added bio-products).

Research & Demonstration Collaboration: The Working Group includes the

University of Florida, Florida Energy Office, U.S. Department of Energy, U.S. Department of Agriculture, farmers and land owners, commercial seed companies (e.g., sweet sorghum), sustainable land use and restoration initiatives, electric utilities, manufacturing companies, ethanol biofuel producers, and others.

Goals & Objectives: Through collaboration in the fields of agriculture and biomass engineering technologies, the Working Group's focus is in four areas:

Displace Coal Use: In generating electricity in the U.S.,

~90% of all CO2 emissions come from burning coal.

Displace Oil Use: ~70% of all oil consumption in the U.S.

is within the transportation sector. Also in Florida, ~31%

of electricity generation came from oil in 2005.

Create Sustainability: To develop advanced agriculture &

environmentally proactive land use methods to provide

sustainable biomass fuel feedstocks.

Increase Industrial Competitiveness: As plants close &

jobs are shipped overseas, U.S. Manufacturing has lost

its competitive advantage in the global economy.

By implementing innovative renewable and sustainable biomass energy technologies, not only can environmental (CO2) and energy independence (foreign oil imports) goals be realized -- but U.S. Manufacturing can regain competitiveness by lowering energy costs from fossil fuels (oil, natural gas, coal).

Biomass Energy & Global Warming: By remembering the basic science of photosynthesis, a

key aspect of our biomass research effort can be easily understood.

Since plants and trees absorb and store

atmospheric carbon as they grow, growing and

using biomass energy crops reduces the level of CO2 emissions into the

atmosphere -- which may be creating Global Warming Climate Change.

Biomass Energy & Global Warming: By remembering the basic science of photosynthesis, a

key aspect of our biomass research effort can be easily understood.

Since plants and trees absorb and store

atmospheric carbon as they grow, growing and

using biomass energy crops reduces the level of CO2 emissions into the

atmosphere -- which may be creating Global Warming Climate Change.

The science behind this Strategy to reduce greenhouse gas levels

is accomplished in two ways: First, biomass energy from crops is "carbon

cycle neutral" just like other forms of renewable energy such as

wind or solar power. Second, growing energy crops creates a

"carbon sink" through terrestrial carbon sequestration

by increasing soil organic matter/carbon through

crop root systems and soil chemistry management practices such as:

Recycling the waste stream bagasse/presscake from

ethanol feedstock (e.g., sorghum, sugarcane).

Using pro-active carbon management farming practices

(e.g., no till, legume rotation crops, etc.).

Recycling the char from pyrolysis technologies (e.g.,

biochar from coking the pyrolytic liquids from the oxygen

starved biomass gasification). (1)

According to a United Nations whitepaper on biochar, the avoided emissions of greenhouse gases are between 2 and 5 times greater when biochar is applied to agricultural land than used solely for fossil energy offsets.

| (1) For example, according to soil scientists at the University of Florida, for each soil application of ~10 tons per acre of biochar (a carbon content of ~80%), soil carbon content would increase 1%. Optimum target levels of carbon in Florida soils may be between 6% to 15%. |

Because of this creation of a "carbon sink" (a

component which solar and wind energy do not have), we believe

that bioenergy from closed loop energy crops represents the most effective choice in

"alternative energy" options to address Global Warming.

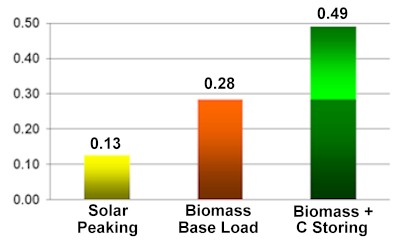

Carbon Reductions of Renewable Energy Options

(Carbon ton/MWh)

For a full discussion why renewable energy base load options such as geothermal or biomass may be more effective than solar or most wind peaking energy options in addressing CO2 emissions, go to our Quick Facts Webpage.

Also, it's important to note that our biomass research and commercial demonstration is using environmentally damaged lands, such as closed mining sites. According to NASA Scientists, one-fifth of the carbon dioxide released annually from fossil-fuel emissions could be "sequestered" by planting energy crops on marginal lands of this type. Hopefully, our work can help create a "Global Model", where thousands of acres now largely considered wastelands can have productive agriculture and environmental use.

Also, it's important to note that our biomass research and commercial demonstration is using environmentally damaged lands, such as closed mining sites. According to NASA Scientists, one-fifth of the carbon dioxide released annually from fossil-fuel emissions could be "sequestered" by planting energy crops on marginal lands of this type. Hopefully, our work can help create a "Global Model", where thousands of acres now largely considered wastelands can have productive agriculture and environmental use.

For marginal lands such as mining (phosphate, coal, etc.), pre-mined lands were most likely in native forest for hundreds/thousands of years. As such, these sites' soils were probably at carbon saturation. After mining however, empirical research is clear that post-mined lands have little soil carbon.

Thus, any incremental build-up of carbon from post-mined sites (starting from a low percentage close to zero) to a new carbon saturation level (present before mining) would be creating a permanent carbon sink. This concept of "incremental build-up" of carbon levels on mined lands is illustrated in the yellow bar of the graph below.

Carbon Saturation Levels of Pre and Post Mined Soils

Also, empirical research (Lehmann, 2006) suggests that the stable component of carbon humus (e.g., biochar) can be added to soils and is not subject to a carbon saturation point.

Biomass Energy & Pollution: Because energy crop fuel contains almost no sulfur and has

significantly less nitrogen than fossil fuels -- reductions in

pollutants causing acid rain (SO2) and smog (NOx) may be

realized -- improving our air quality. An additional

environmental benefit is in water quality, as energy crop fuel

contains less mercury than coal. Also, energy crop farms using environmentally pro-active designs will create water quality filtration zones, uptaking and sequestering pollutants such as phosphorus and particulates from soils that leach into water bodies.

Biomass Energy & Agriculture: What if the next big oil or natural gas field wasn't in places like the Middle East or Venezuela -- but fields of energy crops (trees, sorghum, switchgrass) grown in Florida and the Southeastern U.S.?

In ongoing research and commercial demonstration (best management agricultural and environmental practices) efforts, "energy crop farms" of non-invasive eucalyptus trees

and various row crops (e.g., soybeans, sweet sorghum, sweet potatoes, energycane) has been established on closed

phosphate mining marginal lands (non-irrigated) in central Florida.

The Project reflects decades of tree research conducted by the

University of Florida and Shell Energy to produce

"Super

Trees" which may grow 20 feet a year (yielding 32 green tons

and 16 dry tons per acre per year).

The Project reflects decades of tree research conducted by the

University of Florida and Shell Energy to produce

"Super

Trees" which may grow 20 feet a year (yielding 32 green tons

and 16 dry tons per acre per year).

Also, significant collaboration is occurring with sorghum seed companies in the development and/or commercialization of varieties (F4 hybrids, cultivars) producing high yields (~30 green tons per harvest) and high Brix (sugar content) that can be grown year-round in Florida's warm climate providing crop feedstocks (not competing with bard markets) for ethanol and other biofuel production. Also, significant collaboration is occurring with sorghum seed companies in the development and/or commercialization of varieties (F4 hybrids, cultivars) producing high yields (~30 green tons per harvest) and high Brix (sugar content) that can be grown year-round in Florida's warm climate providing crop feedstocks (not competing with bard markets) for ethanol and other biofuel production.

Another important

aspect of "Energy Crops" is that they can also represent a

sustainable renewable energy resource -- since our trees, certain row crops like sugarcane and possibly sorghum, will re-grow

after each harvest (coppice, ratoon) -- allowing multiple harvests without having to re-plant (called short rotation crops).

A key aspect of our agriculture research and demonstration efforts is the development of Strategies to vertically integrate Farming into Bioenergy projects -- allowing Farmers to participate in a profitable "process end" (e.g., biofuel ethanol production) of agriculture rather than just selling a commodity based raw product (e.g., corn, soybeans, etc.). All of these Strategies have a common nexus to create "value added" products and services to become a low cost Producer.

If our team of scientists, engineers, farmers, and environmentalists

are successful, energy crops could provide:

A clean alternative energy biofuel for power plants.

Feedstocks for ethanol (cellulose or sugar/starch

platforms) and biodiesel.

New cash crops to farmers & rural economic development

Greater Energy Independence (foreign oil & natural gas).

Productive use of environmentally damaged lands.

Biomass Energy Crops & Soils: In addition to carbon terrestrial sequestration, there are also tremendous agriculture and environmental benefits in growing energy crops -- where increases in soil organic and carbon matter (SOM, SOC) can result in: Biomass Energy Crops & Soils: In addition to carbon terrestrial sequestration, there are also tremendous agriculture and environmental benefits in growing energy crops -- where increases in soil organic and carbon matter (SOM, SOC) can result in:

Greater efficiency of soil nutrients for plants, requiring

less fertilizer (e.g., holding of cations and anions).

Improvements in water hydrology (e.g., natural water

flow) and quality (e.g., reduction in phosphorus and

nitrogen loading).

Biomass Energy Engineering for Electricity Generation: The power plant engineering behind our efforts is also

innovative, using an approach called biomass co-firing. With co-firing,

an existing power generation facility is modified to allow use

of energy crop fuel -- changing the fuel mix from a current 100%

dependence on fossil fuels (such as coal, oil, natural gas) to

approximately 5% biomass fuel and 95% fossil fuels.

Biomass Energy Engineering for Electricity Generation: The power plant engineering behind our efforts is also

innovative, using an approach called biomass co-firing. With co-firing,

an existing power generation facility is modified to allow use

of energy crop fuel -- changing the fuel mix from a current 100%

dependence on fossil fuels (such as coal, oil, natural gas) to

approximately 5% biomass fuel and 95% fossil fuels.

While displacing relatively small percentages of fossil fuel

use with biomass energy crops may

not sound like much, it is very significant when recognizing the

tremendous size of electricity generation facilities. For

example, co-firing energy crops at just one medium size power

plant would be the equivalent of installing over

41,000

large solar panels -- or in reducing CO2 emission levels,

by removing approximately 17,000 cars off the road.

Co-utilizing "Energy Crop Fuel" especially with coal is both

effective and economically promising because it doesn’t require

major changes in existing technology at power plants.

Instead of building new power generating facilities, which would

ultimately result in higher costs to the consumer,

we are working with scientists and engineers

to change the fuel blend. It’s a novel approach to creating

Renewable Energy,

and if it works, there’s potential for immediate commercial use

by electric utilities offering

their customers a low cost option to purchase "Green

Energy".

In biomass co-firing, there are three primary approaches to biomass fuel delivery into the existing power plant: Solid Fuel Blending; Solid Fuel Direct Injection; and External Gasification.

Examples include: (1) Blending coal and biomass fuel together for a cyclone coal unit or through biomass torrefaction in coal pulverized coal units; (2) Directly injecting only biomass fuel through dedicated fuel ports into a pulverized coal unit; (3) Creating biogas (biomass syngas) in an external gasifier and then piping the hot gas into an existing coal, oil, or natural gas boiler.

In torrefaction, biomass is heated to temperatures of ~300 degrees C. This produces a charcoal-like material that can be pelleted. Torrefied pellets have 3 to 4 times the energy density of timber and are water repellent, allowing for storage outside. The hemicellulose structure is broken down and the cellulose fibers are shortened, improving the milling properties (especially advantageous for pulverized coal power plants).

An intriguing aspect of the third option is the potential to use the biogas high in the boiler's re-burn zone -- possibly avoiding the need to install costly pollution control equipment (e.g., Selective Catalytic Reduction or SCR) at a coal unit. Engineering research suggests that the "hot tar" fraction in the "hot raw" biogas is particularly reactive and may reduce NOx emissions between 50% and 70%.

Working with Electric Utilities, U.S. Department of Energy Labs (NETL, NREL, ORNL), the Electric Power Research Institute (EPRI) and Others -- we have performed biomass co-firing engineering research (called "test burns") on all major combustion technologies of cyclone, pulverized coal, and combined cycle gasification (IGCC) units.

Biomass Energy Engineering for Industrial Applications: A major strength of biomass gasification technology is its flexibility as to the end-use process. Within the Industrial and Manufacturing sector, biomass gasification is used for electricity, steam, co-generation, and heat for product drying. Also, with developing advancements in engineering technology,

new generation ethanol plants can actually use a gasifier to make syngas, which is then transformed into ethanol by catalysts or enzymes.

Biomass Energy Engineering for Industrial Applications: A major strength of biomass gasification technology is its flexibility as to the end-use process. Within the Industrial and Manufacturing sector, biomass gasification is used for electricity, steam, co-generation, and heat for product drying. Also, with developing advancements in engineering technology,

new generation ethanol plants can actually use a gasifier to make syngas, which is then transformed into ethanol by catalysts or enzymes.

Biomass gasification designs can generally be classified into two broad categories producing a low (~135 Btu/scf) to medium (~400 Btu/scf) Btu gas -- (compared to ~1,000 Btu/scf for natural gas):

Fixed Bed (e.g., HMI Wellman Galusha, Nexterra updraft

design).

Fluidized or Bubbling Bed (e.g., Taylor Biomass Energy).

Pollution control technology often associated with industrial bio-gasification is a baghouse for particulate matter emissions.

In common industrial applications (e.g., process heat for product drying), the hot raw gas from the biomass gasifier is sent either to a heat exchanger or an electrostatic precipitator. If process steam is required, a heat recovery steam generator (HRSG) or package boiler would be used.

Another industrial application is on-site distributed generation (electricity) using cleaned bio-gas (through an electrostatic precipitator, or ESP) into a G.E. Jenbacher engine (up to ~3 Mw's per engine) or comparable engine. It is our understanding that the G.E. Jenbacher engine's heat rate (Btu's/kWh) is ~8,500 and has a capital cost of ~$600 per kW.

Other end-uses include synthesis of high quality gaseous fuels such as hydrogen or synthetic natural gas, and synthesis of liquid fuels such as methanol, diesel, gasoline jet fuel, and ethanol.

In achieving reductions in greenhouse gas emissions, developing bioenergy projects for industrial processes is extremely important, especially for projects which use agricultural by-products. In achieving reductions in greenhouse gas emissions, developing bioenergy projects for industrial processes is extremely important, especially for projects which use agricultural by-products.

Combined, percentages from industrial processes (16.8%) and agriculture by-products (12.5%) would represent the single largest source of total world-wide greenhouse gas emissions at ~30% -- much greater than either electricity generation or transportation fuels.(2)

| (2) Source:

Wikipedia -- from the Emission Database for Global Atmospheric Research version 3.2, fast track 2000 project. |

Biomass Energy Economic Incentives: There are significant existing and evolving federal incentives to use biomass energy including tax credits, accelerated tax depreciation, federally guaranteed financing, and Cap and Trade carbon credits (or carbon tax avoidance).

Biomass Energy Economic Incentives: There are significant existing and evolving federal incentives to use biomass energy including tax credits, accelerated tax depreciation, federally guaranteed financing, and Cap and Trade carbon credits (or carbon tax avoidance).

Production Tax Credit (PTC) (3) : Section 45 of the Internal Revenue Code provides a tax credit of up to ~2˘ per kWh for electricity generation from biomass feedstock. It must be noted however that since the PTC is a direct dollar-for-dollar reduction in taxes (versus a deduction to taxable income) the tax credit's value must be adjusted to reflect its true economic value (e.g., dividing 2˘ by 1 minus the corporate tax rate of 35%). Thus, the true production cost value of the PTC is up to ~3˘ per kWh. Making this "gross-up" in the PTC stated value is extremely important in order to make an apples-to-apples comparison of the production cost (per MMBtu, kWh) of biomass energy versus other fuel options (oil, natural gas, coal, nuclear).

For example, if the production cost of using closed loop biomass fuels was 3˘ per kWh (e.g., crop cost, O&M, capital financing costs, etc.), the net production costs would be zero. It is this "net" number which must be compared to the cost per kWh of other electricity generation options (i.e., cost to the consumer and also called revenue requirements).

Under the recently passed Economic Stimulus Act, a biomass project's tax owner can either elect to take (1) the PTC on a yearly basis for 10 years; or (2) as a one-time lump sum cash credit in the first tax year after commercial in-service. Under this lump sum option, 30% of the capital cost would be reimbursed under a program administered by the U.S. Treasury (which would enhance the payback period of a project's capital investment). (4)

(3) Each year the PTC is adjusted for inflation. As of June 2009, the PTC for closed loop biomass (dedicated energy crops) is 2.1˘ per kWh and 1.1˘ per kWh for open loop biomass (biomass waste streams such as woodwaste, sugarcane or sorghum bagasse/presscake).

(4) For Combined Heat and Power (i.e., industrial process heat or steam and electricity generation) projects, the lump-sum option is 10% of capital investment (versus the 30%). |

Liberalized Tax Depreciation: In 2008, the Internal Revenue Service ruled privately that the front end of a biomass power plant through the boiler or gasifier, plus pollution control at the back end, can be depreciated over five years (i.e., 5 year MACRS). The power train is depreciated over 15 or 20 years. Also, under the Economic Stimulus Act, 50% of the capital asset may be depreciated (called Bonus Depreciation) in the first year (projects placed in service in 2009, 2010).

Guaranteed Federal Financing: In the Economic Stimulus Act, Congress authorized ~$4 billion in federally backed loan guarantees to finance renewable energy and energy efficiency projects. The program is to be administered by the U.S. Department of Treasury with expected interest rates of ~3% per year.

Carbon Credits: Currently in the U.S. there are no regulations (i.e., through the U.S. Environmental Protection Agency -- EPA) to regulate carbon emissions. Nor has any federal legislation been enacted (e.g., Cap and Trade, Carbon Tax). Thus, all current trading of carbon credits in the U.S. is on a voluntary basis, primarily through the Chicago Board of Exchange -- CBOE). As of April 2009, CO2 credits on the CBOE were trading at ~$1.55 per metric ton of CO2.

However, in the European Union where mandatory Cap and Trade regulation and legislation has been enacted, carbon credits (as of April 2009) were trading at ~$21 (~€16) per metric ton of CO2 on the European Carbon Exchange -- ECX.

In April 2009, legislation was introduced in the U.S. Congress to implement a carbon tax (versus an European type Cap and Trade System based on derivatives). The initial rate would begin at $15 per metric ton of CO2, and increase by $10 each year for 5 years.

CO2 Tax Introduced in U.S. Congress

| Year:

|

Per Metric Ton: |

Per MMBtu: |

Per kWh:(5) |

|---|

| 2010 |

$15.00 |

$0.80 |

0.80˘ |

| 2011 |

$25.00 |

$1.33 |

1.33˘ |

| 2012 |

$35.00 |

$1.86 |

1.86˘ |

| 2013 |

$45.00 |

$2.39 |

2.39˘ |

| 2014 |

$55.00 |

$2.92 |

2.92˘ |

| (5) Above kWh values assume a heat rate conversion of 10,000 from Btu's to kWh's. |

U.S. Government Agencies' Projections of CO2 Prices

Biomass energy projects create carbon credits in two ways:

Fossil fuel displacement in power and/or heat generation.

Carbon soil sequestration by growing energy crops.

In collaboration with the U.S. Department of Energy's Oak Ridge National Lab (ORNL), our soil carbon sequestration work in Florida provides a example of the potential to create carbon credits economic value. Based on the ORNL analysis, ~16 metric tons of CO2 may be sequestered per acre, per year in growing energy crops. With a price of $15 (metric ton), the carbon credits value would be ~$245 per acre, per year.

Biomass Crop Assistance Program: This U.S. Department of Agriculture Program (called BCAP) was authorized by Congress to assist farmers/land owners in the costs of collecting, harvesting, transportation, and storage of feedstocks used in a qualified biomass energy facility (heat, power, advanced biofuels). BCAP provides a matching payment to farmers of up to $45 per dry ton. BCAP is also to be expanded in the future to include the establishment costs of crops.

The Biorefinery Concept: In addition to the above electric utility power plant project work, we are working with Industrial Companies to integrate a variety of biomass raw feedstocks (e.g., cellulose, sugar/starch crops or waste streams) and conversion processes (e.g., biotechnology) into a single facility called a biorefinery at an existing "host" industrial plant:

Steam and Power Co-generation (using syngas).

Fuel Products (e.g., ethanol, hydrnol, pyrolysis bio-oil). (6)

Value Added Products (e.g., chemicals, materials such as

plastics).

| (6) The prrolytic liquids produced from the biogasification process is an equivalent of #6 fuel oil when moisture is 15% or less. |

Our approach in creating a biorefinery is fundamentally the same as the approach used with electric utility power plant co-firing -- where an existing industrial "host" facility is modified for biomass applications utilizing as much of the existing engineering infrastructure as possible (e.g., avoiding high capital costs of a new stand alone bioenergy or biorefinery facility).

From an industrial company's perspective, the economic incentive with this approach is the displacement of higher cost natural gas (and in Florida, also oil) with lower cost biogas in the generation of steam/power (i.e., cogeneration) and/or process heat (i.e., product drying) for the industrial company's "core market" products.

Projections for Natural Gas Prices

($/MMBtu)

(Note: Above prices reflect only the wellhead price of natural gas and do not include any transportation & distribution costs of ~$1.00 per MMBtu.)

Current Fuel Prices

(May 18, 2012)

| Fuel Resource:

|

$'s per MMBtu |

Reference Notes:

|

|---|

| Oil |

$16.67 |

~$97 per Barrel (WTI) |

| Natural Gas(7) |

$2.50 |

Henry Hub |

| Eastern Coal |

$2.44 |

$61/ton (12,500 Btu)(8) |

| Wood for Boilers |

$2.64

| ~$22/green ton(9) |

| Wood for Pellets |

$3.73 |

~$31/green ton(10) |

(7) U.S. Department of Energy's EIA Weekly Update. For natural gas, ~$1.00/MMBtu should be added to the Henry Hub price for transportation & distribution costs.

(8) U.S. Department of Energy's Average Weekly Coal Commodity Spot Prices. Add ~$30/ton (~$1.20/MMBtu) to spot commodity price for transportation costs.

(9) Hog fuel wood chips in Florida with ~48% moisture and 4,160 btu's per pound. On a dry basis, this equates to a price of ~$38 per ton with ~8,000 btu's per pound.

(10) Current price ranges from $28 to $34 per green ton. Pellet plants typically want roundwood (logs) of pulpwood grade and is therefore a pulpwood price.

|

Example of Biomass Energy in Florida: While there are compelling economic, environmental, and national security (foreign oil dependency) arguments why biomass energy resources need to be developed in the U.S., there is perhaps no greater illustration of this than in Florida.

While oil used for electricity generation is only 1.5% nation-wide, oil is ~10% of the electric utility fuel mix in Florida (~7 times the national average). During 2008 (where oil prices peaked at ~$150 per barrel), electricity prices in Florida were ~30% greater than other States in the southeast.

Florida Vs. U.S. Oil Use for Electricity Generation

An illustration of low hanging fruit for reducing foreign oil dependency in Florida would be the installation of a new external biomass gasifier to an existing electric utility oil fired boiler (e.g., a fuel switching co-firing strategy discussed previously).

Biomass Energy Options Capital Cost: The below data reflects the capital cost per kW for electricity generation. For industrial processes like product drying, the capital costs of a wet ESP (i.e., biogas clean up) and Jenbacher engine would be replaced with a heat exchanger or a low pressure steam boiler.

The below U.S. Department of Energy data compares biomass gasification and co-firing versus other similar base load generation options from fossil fuels(11) .

Biomass Energy Production Cost (O&M): Through our biomass gasification project development efforts in Florida, the below chart is an approximation of the production cost of implementing biomass gasification.

It should be noted that the "net" production cost of biomass gasification would be even lower when factoring in economic incentives such as the production tax credit (I.R.C. Section 45) and carbon credits.

| Biomass Gasification Production Costs:

|

$'s per MMBtu |

|---|

| Biomass Fuel Cost |

$2.26 |

| Labor Personnel Cost |

$0.66 |

| Capital Costs |

$0.98 |

| Operation & Maintenance Costs |

$0.48 |

| Utility Costs |

$0.36 |

| Administrative Costs |

$0.18 |

| Total Production Costs |

$4.92 |

The following table illustrates this concept of net cash production cost (also referred to as revenue requirements or the necessary price to recover all costs) reflecting (A) carbon credits at ~$20 per metric ton; (B) the tax cash savings from liberalized tax depreciation (bonus depreciation under the Economic Stimulus Act).

| Net Cash Costs:

|

Year 1 |

Year 2 |

Year 3 |

Year 4+ |

|---|

| Production Costs |

$4.92 |

$4.92 |

$4.92 |

$4.92 |

| Carbon Credits |

($1.00) |

($1.00) |

($1.00) |

($1.00) |

| Cash Tax Benefits |

($1.00) |

($0.59) |

($0.31) |

- |

| Total Net Costs |

$2.92 |

$3.33 |

$3.61 |

$3.92 |

Putting It All Together: The below biomass diagram flow chart illustrates all the major project concepts we are trying to achieve in integrating sustainable biomass renewable energy and land use development.

Biomass Energy & Native Habitats: Also included in this Research Effort are special project

advisors from leading environmentalists, such as the

Sierra Club, Audubon Society, and the Florida Fish & Wildlife Conservation

Commission -- ensuring that natural wildlife habitats are

preserved and enhanced.

A key aspect of this environmental habitat work effort is using energy crops as "Bridge Crops" to reclaim/restore severely damaged closed phosphate mining sites.

Biomass Energy & Native Habitats: Also included in this Research Effort are special project

advisors from leading environmentalists, such as the

Sierra Club, Audubon Society, and the Florida Fish & Wildlife Conservation

Commission -- ensuring that natural wildlife habitats are

preserved and enhanced.

A key aspect of this environmental habitat work effort is using energy crops as "Bridge Crops" to reclaim/restore severely damaged closed phosphate mining sites.

As a non profit 501-c-3 environmental corporation, The Common Purpose Institute makes all the information available on the treepower.net website free to the general public. However, all information is copyright protected and any use of this information for commercial/profit purposes (e.g., such as engineering consulting companies) must be approved by the Common Purpose Institute.

|